Hydraulic servo cylinders are widely used in versatile industrial applications such as machine tools, test rigs for any kind of components, industrial robots, autonomous manufacturing systems and special applications in laboratories.

In general, they are typically used whenever a smooth movement with low friction, fast dynamic response and possible radial forces are required.

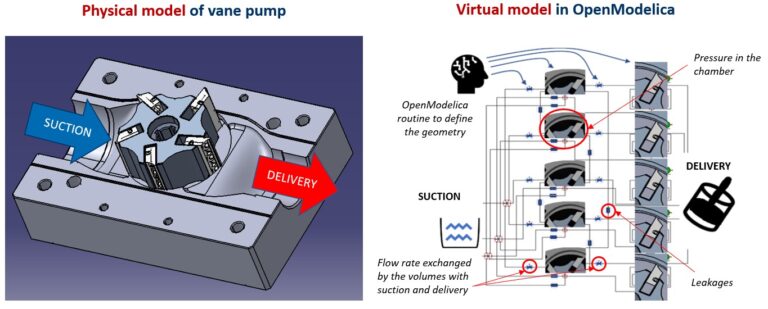

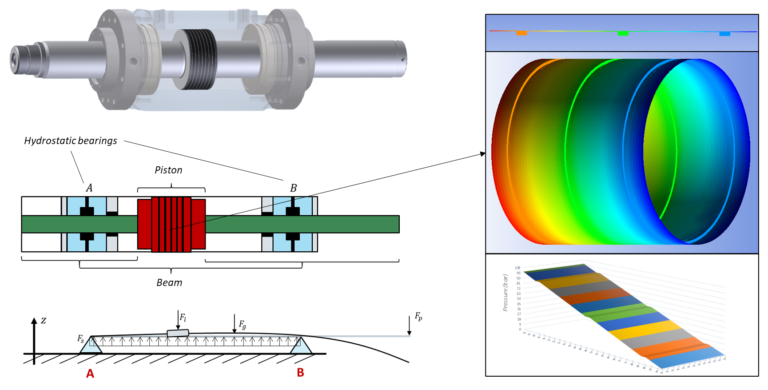

Hydrostatic journal bearings with pockets are used on servo cylinders’ rod ends in order to guarantee the bearing of high loads, reduce friction, remove wear and allow smooth and controllable displacement of the actuator.

The design and manufacturing of these elements is challenging since the good operation relies on the very small tolerances required to bear the load on the cylinder and to reduce leakages.

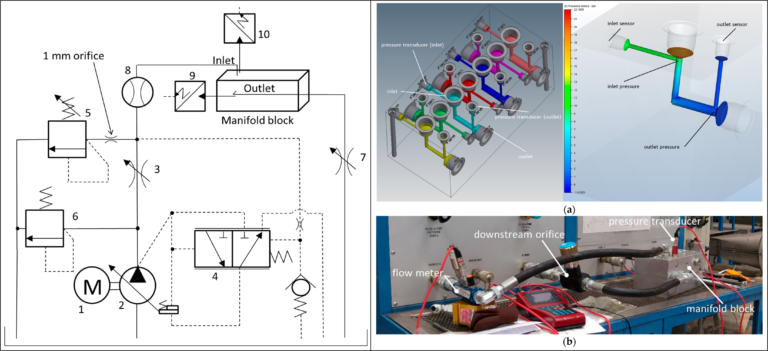

Lubricated interfaces in fluid power components are one of the most critical issues to be carefully designed for assessing a smooth behaviour and good efficiencies in a system. Moreover, they are fundamental to analyse the complex phenomena determining the positive displacement pumps and motors efficiency and also fault behaviour.

In this work, a 2D fluid dynamic model of hydrostatic journal bearing is presented. The model is composed by a system of equations, created by SmartFluidPower, written in Modelica language and entirely solved in OpenModelica environment.

This work concerns the first part of a research activity in which a virtual model and test tool for hydrostatic journal bearing with pockets are created.

The model proposed has the aim to explore the extreme and critical operating conditions of the servo-cylinder and to help and/or improve the design phase: the results show a significant influence of eccentricity and manufacturing tolerances and, therefore, an accurate choice of the design parameters must be followed to look for the best configuration.

With the help of an industrial partner the numerical model is tested and validated: at the end, a virtual design tool is created for industrial designers to help and guide their work.

Besides the specific results obtained regarding the design of the bearings, the work also demonstrates a different use of OpenModelica environment: a pure equations solver of which results are used to create an industrial virtual tool that helps the designer to simulate different configurations and look for the optimal solution.